Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

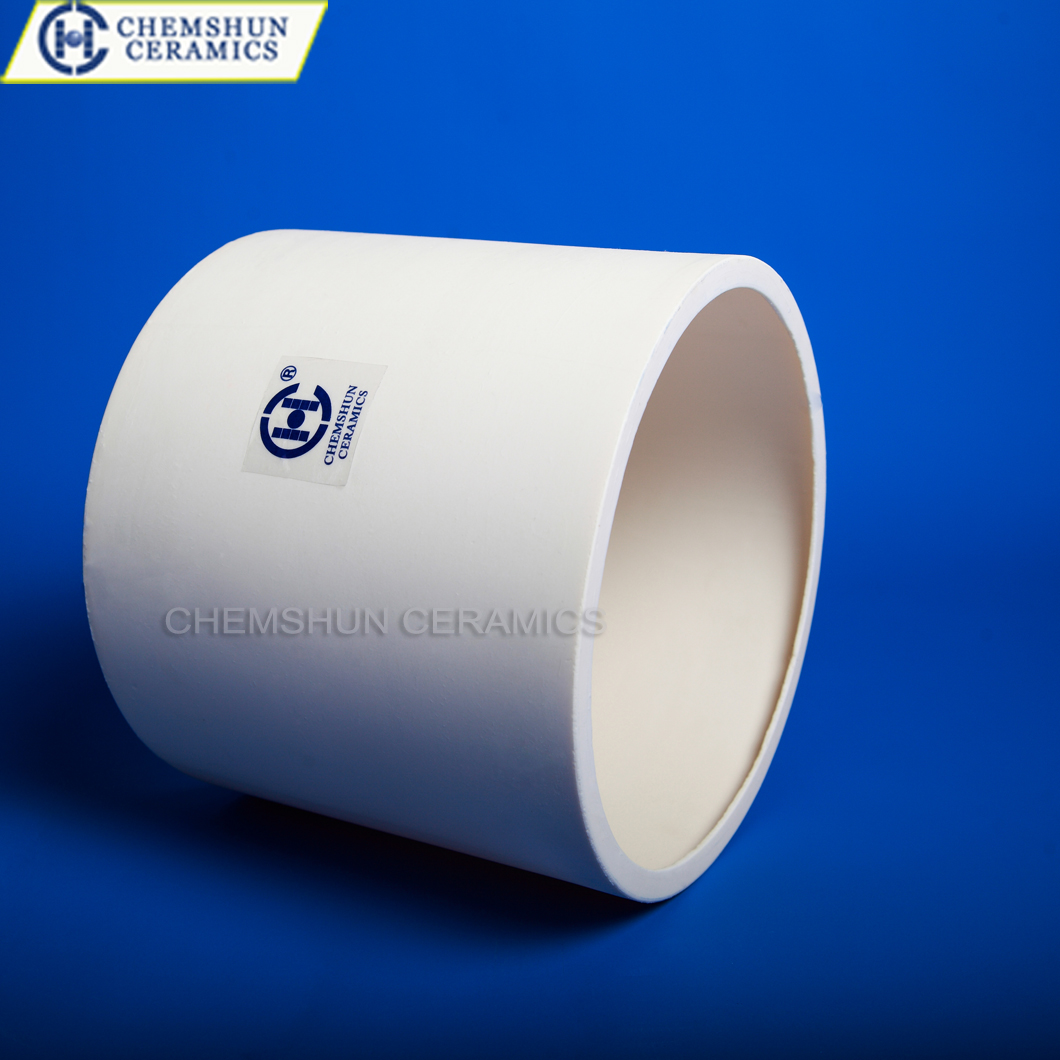

What's the application of 997 Ceramics

As an important ceramic material, 997 alumina ceramic has good sliding properties, low density, bioinertness and food compatibility, excellent electrical insulation, medium to extremely high mechanical strength, and very high compressive strength. , high hardness, moderate thermal conductivity, high corrosion resistance and wear resistance and other characteristics. These properties make 997 alumina ceramics widely used in many fields.

1. Machinery manufacturing field

The field of machinery manufacturing requires a large amount of high-precision, high-wear-resistant materials, and alumina ceramics are the ideal choice. 997 high-purity alumina ceramics have extremely high hardness and wear-resistance and can be used to manufacture high-precision, high-wear-resistant materials. Mechanical parts, such as bearings, gears, seals, etc. These parts play a vital role in mechanical equipment, so using alumina ceramics can improve the life and performance of the equipment.

2. Automobile manufacturing field

The automotive manufacturing field requires the use of a large number of materials that are high temperature resistant, wear resistant, and have low friction coefficients, and 997 high-purity alumina ceramics are the ideal material choice. It can be used to make engine parts, brake pads, cylinder liners, etc. These components play an important role in the operation of the car, so using alumina ceramics can improve the performance and safety of the vehicle.

3. Medical field

The medical field requires the use of materials with biocompatibility, wear resistance, corrosion resistance and other properties, and 997 high-purity alumina ceramics can meet these requirements. Can be used to make artificial joints, dental implants, etc. These applications require contact with the human body, so using alumina ceramics can reduce the risk of rejection and infection and improve medical outcomes.

4. Other fields

In addition to the above fields, 997 high-purity alumina ceramics can also be used in aerospace, electronics, energy and other fields. It can be used to manufacture high-temperature stoves, electronic components, solar panels, etc. These applications require high temperature resistance, corrosion resistance, insulation and other properties, and alumina ceramics can meet these requirements

Pingxiang Chemshun Ceramics can customize and produce 997 alumina ceramics in various shapes and uses for customers. Welcome to consult.