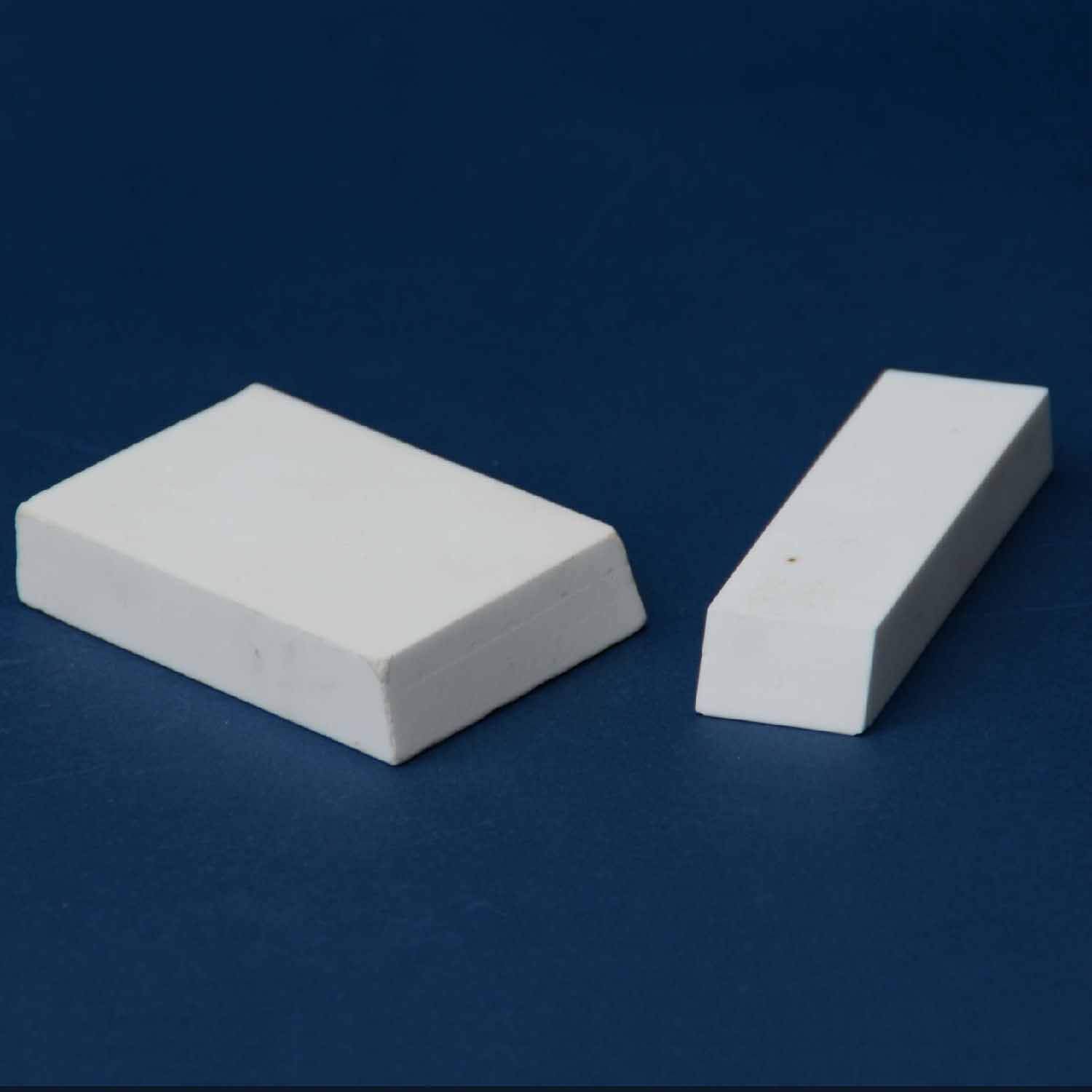

Product Name:Wear Resistant Linings

- Product Category:

- Product Details:

High alumina ceramic welded tile with hole provide excellent abrasion and impact resistance for industrial friction equipment. frequently-used as wear liner for hopper, cyclone , Chute ,separator, bunker, impellers and agitators, fan blades and fan casings, chain conveyors, mixers ect, - E-Mail:

Wear Resistant Linings

Chemshun Alumina ceramics as wear resistant lining for protecting material handling system equipment from abrasion damage.

Product description:

High alumina ceramic welded tile with hole provide excellent abrasion and impact resistance for industrial friction equipment. Alumina tile frequently-used as wear liner for hopper, cyclone , Chute ,separator, bunker, impellers and agitators, fan blades and fan casings, chain conveyors, mixers ect, it is easily weld installation to machine no matter extremely high or low temperature working environment, also best wear resistant choice for dynamic operation equipment.

Chemshun Ceramic Product Salient Property:

> Excellent wear and abrasion protection property

> Lower production and maintenance cost

> Excellent corrosion resistance property

> Excellent impact resistance property

> Excellent heat resistance property

> Easy to handle size and weight

> Fast and safe installation

Chemshun Ceramic Advantage:

> Afford the standard and pre-engineered tiles

> Professional technical team to afford CAD designs

> Professional installation team to afford install service

> Well established process as per international standards

Technical parameters:

| Technical Data of Alumina ceramic product from Chemshun | |||

| Properties | Unit | Typical Value | |

| Alumina Content | % | 92 | 95 |

| Density | g/cc | ≥3.6 | ≥3.7 |

| Water Absorption | % | None | None |

| Rockwell Hardness | HRA | 80 | 85~88 |

| Compressive Strength | 20ºC,Mpa | 850 | 950~1000 |

| Flexural Strength | 20ºC,Mpa | 280 | 300 |

| Max Using Temp | ºC | 1250 | 1250 |

| Thermal Expansion Coefficient | 1x10-6/ºC | 7.3 | 8.3 |

| Application Industry from Chemshun | ||

| Industry | Equipment System | Equipment parts |

| Cement | Pre-blending system for crashing limestone and crude fuel | Chute,Bunker,Pulley lagging ,discharge cone |

| Raw mill system | Feed chute,Retaining ring, Scraper plate,Seal ring, Pipeline,Bucket guard,Cyclone, Powder concentrator body,Bunker | |

| Cement mill system | Chute,Bunker,Fan vane wheel, Fan casing,Cyclone,Circular duct, Conveyer | |

| Ball mill system | Pulverizer exhauster's body and vane wheel,Powder concentrator's body,Pulverized coal's pipeline, Hot air duct | |

| Sintering system | Inlet/Outlet bend,Wind value plate ,Cyclone,Chute,Dust collector's pipe | |

| Afterheat system | Separator's pipeline and wall | |

| Steel | Raw material feeding system | Hopper,Silo |

| Batching system | Mixing bunker,Mixing barrel ,Mixing disk,Disk pelletizer | |

| Sintered material transport system | Hopper,Silo | |

| Dedusting and Ash discharge system | Dedusting pipeline,Bend,Y-piece | |

| Coking system | Coke hopper | |

| Medium-speed mill | Cone,Separation buffles,Outlet pipe ,Pulverized coal's pipeline,Burner cone | |

| Ball mill | Classifier,Cyclone separator,Bend ,Powder concentrator's Inner shell | |

| Thermal power | Coal handling system | Bucket wheel machine,Coal Hopper ,Coal Feeder,Orifice |

| Ball mill system | Separator's pipe,elbow and cone ,Coal mill's elbow and straight tube | |

| Medium-speed mill | Coal mill body,Separation buffles ,Cone,Pipeline,Elbow | |

| Fall mill | Pulverized coal's Pipeline and Elbow | |

| Dedusting system | Dedusting's Pipeline and Elbow | |

| Ash discharge system | Fan duster's shell,Pipeline | |

| Port | Transporting material system | Bucket wheel machine's disk and hopper,Transfer point's hopper,Unloader's hopper, |

| Smelting | Transporting material system | Measuring hopper,Coke hopper ,Vibrating screen's chute,Head valve, Intermediate Bin,Tail bin |

| Batching system | Batch hopper,Mixing machine | |

| Burning system | Ash bucket,Pump calcine tube,Hopper | |

| Dedusting system | Dedusting's Pipeline and Elbow | |

| Chemical | Transporting material system | Hopper,Silo |

| Dedusting system | Dedusting's Pipeline and Elbow | |

| Processing equipment | Vibromill liner | |

| Coal | Coal handling system | Bucket wheel machine,Coal Hopper ,Coal Feeder,Silo |

| Coal washing system | Hydrocyclone | |

| Mining | Transporting material system | Hopper,Silo |

Chemshun wear resistant liner tile package pictures :

Product Technical Data (1:wear resistant ceramic)

Chemshun Ceramics also recommends these other Alumina Ceramic Tiles:

Related Keywords :

Wear resistant lining alumina ceramic block abrasion resistant linings wear resistant ceramic Tile| Company name: | Please fill in your company name |

| * E-mail: | |

| Source: |

|

| * Inquire intention description: | |

| Please fill in the quantity and description of Inquire products for uniform stocking. | |

Related News

- How do chemshun control the quality of wear resistant ceramic products?

- Weldable tile and Its Installation

- The China Minmetals Corporation’s Peru Las Bambas copper project officially put into operation & Pingxiang Chemshun Ceramic wear resistance ceramic wear liner used in copper mine

- Minimum wear and maximum value

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

ADD:Non-metal area of shangliuyuan, Economic development zone, pingxiang city, Jiangxi province, P.R.China

- comments in total【Write a Review】Customer Reviews