Product Name:Foundry Ceramic Bead

- Product Category:

- Product Details:

Using Chemshun foundry ceramic bead, the Casting industry can successfully hit the mark of zero of solid waste during the casting process. - E-Mail:

Chemshun ® Foundry Ceramic Bead is a China environmental protection intelligent casting an important pushing hands.

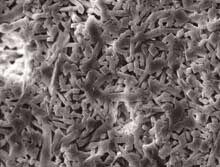

Chemshun foundry ceramic bead also called Casting Ceramic beads is a high temperature (up to 1800 degree centigrade ) foundry material with the spherical ceramic beads. With the excellent advantage of no crushing during foundry process and more than 50 times regenerative using, It’s become a popular new generation foundry ceramic beads on worldwide casting market. Using Chemshun foundry ceramic bead, the Casting industry can successfully hit the mark of zero of solid waste during the casting process, meanwhile the surface of casting and quality of casting big improved. Chemshun Foundry Ceramic Bead is a China environmental protection intelligent casting an important pushing hands.

Chemshun Foundry Ceramic Beads features:

Raw material : Chemshun foundry ceramic beads is made of mullite crystile, Al2O3 content is around 45% (wt), Fe2O3<1% (wt). The material is the shell-shaped with uniform composition and compact structure.

Characters:

>Uniform composition and stable grain size distribution

>Excellent Angle Coe, roundness shape, excellent fluidity and filling efficiency made it suitable for all special shape of cast

>Excellent recycling performance, up to more than 50 times cycles.

>High refractoriness (up to 1800 C)

>Low thermal expansion rate

>Excellent resistance to crushing, wearing and thermal shock

>Excellent collapsibility and not easy to sand, but cleaning casting easily

>A Clean and environmental protection material, the basic realization of zero emissions of solid waste.

Application:

>Special casting (investment casting, casting a variety of ways disappear film, V method, VRH method, etc.), particularly suitable for low-expansion temperature coated sand production

>Sand casting

>Peening

Typical Chemical Composition

Al | Si | Fe | Ti | Mg | Ca | Other | |

CCB-1 | 43.5% | 53.0% | 1.5% | 0.55% | 0.3% | 0.2% | < 0.2% |

CCB-2 | 50.0% | 47.0% | 1.2% | 0.50% | 0.3% | 0.2% | Microscale |

CCB-3 | 60.0% | 38.0% | 1.0% | 0.45% | 0.3% | 0.2% | Microscale |

Per-formance Index

Angular | ≤ 1.1 | ||

Refractoriness | CCB-1 :1750℃ | CCB-2 : 1800℃ | CCB-3 : 1825℃ |

Heap Density | CCB-1 :1.40(g/cm3) | CCB-2 :1.45(g/cm3) | CCB-3 :1.55(g/cm3) |

Thermal Expansion Rativ | 0.11% | ||

PHvalue | 7-8 | ||

Thermal Conductivity | 5.5W/M·K (1200℃) | ||

Related Keywords :

Foundry ceramic bead wear ceramic liner abrasion resistant tile alumina ceramic lining| Company name: | Please fill in your company name |

| * E-mail: | |

| Source: |

|

| * Inquire intention description: | |

| Please fill in the quantity and description of Inquire products for uniform stocking. | |

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

ADD:Non-metal area of shangliuyuan, Economic development zone, pingxiang city, Jiangxi province, P.R.China

- comments in total【Write a Review】Customer Reviews