![]() Alumina Grinding Balls for Mining

Alumina Grinding Balls for Mining

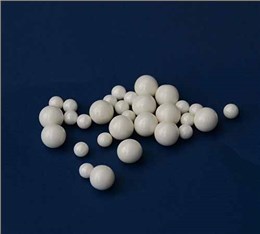

Chemshun ceramic Alumina grinding balls media for miming is small size ceramic balls or Alumina ceramic beads

Chemshun Ceramics grinding media for mining is small size ceramic balls or ceramic beads , used in high intensity stirred mills for fine and ultra fine grinding, The ceramic grinding media with different composition and size , and good feature of high impact resistance , The property of inert and no pollution , the media can replace the traditional steel and chrome steel grinding media for applications where downstream processes are sensitive to surface chemistry and also could avoid to the generation of slimes which combined with those traditional media’s angular shape and high wear rates.

Item | Main composition | Diameter Range (mm) | Density (g/cm3) | Color | Vickers Hardness (kgf/mm2) | Application Suggestion |

CS -26 | Al2O3:45~60% SiO2:34~45% | 0.5~20 | 2.6~2.8 | White | 700-800 | It’s suitable for the stirred mill such as Metso’s SMD and fine milling process of soft materials with low slurry density. |

CS-32 | Al2O3, SiO2 ZrO2 | 0.5~20 | 3.2~3.3 | White | 900-1000 | It’s suitable for the stirred mill such as Metso’s SMD and milling the hard minerals. |

CS- 36 | Al2O3:>90% | 0.4~25 | 3.5~3.75 | White | 1300~1350 | It suitable for the Nano-size material grinding. |

CS- 40 | ZrO2:55~65% SiO2:30~35% | 0.4~5.0 | 4.0~4.2 | White | 1000~1050 | It’s suitable for the high linear velocity conditions. Example, vertical and horizontal stirred mill, such as Outotec’s HIGMill, Glencore’s Isa mill. FLSmidth’s VXP mill. It can grind the high density slurry of minerals. |

CS-52 | ZrO2:80~90% Al2O3:10~20% | 0.4~5.0 | 5.1-5.3 | White | 1350~1450 | It suitable for the hard materials’s superfine mills with high speed (up to 14m/S) and high energy input. For example: Outotec’s HIG mill. Flsmidth VXP. |

CS -60 | ZrO2:94~96% Y2O3:4-6% | 0.2~40 | 5.95~6.05 | White | 1300~1400 | 1.Chemical materials, paint, printing, ink, pigment. 2.Advanced ceramics pastes or powder. 3.Electronic pastes: goldsilver, platinum, cuprum, nickel. 4.Food stuff, pharmaceuticals, cosmetics. |

CS-62 | ZrO2:93~94% CeO2:6~7% | 0.6~4.0 | 6.1~6.2 | Yellow Or Brown | 1200~1250 |

Remark: CS-26, CS-32, CS-36, CS-40, CS-52 are suitable for the industries of:

1.Metallic minerals: copper, silver, nickel, Zinc

2.Non-metallic minerals: Kaolin clay, Calcium carbonate, Zirconium Silicate .

3. Coating, paint, ink etc.

Package :

1.1000kg/jumbo bag.

2.25kg/bag, small bags put into jumbo bag.

3.CS-52, CS-60, CS-62 by plastic drums, then drums fasten on pallet.

Product Technical Data(2- Ceramic Grinding Media)

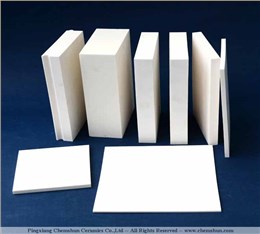

Ceramic Tile Liner

Ceramic Tile Liner Ceramic Tube Liner

Ceramic Tube Liner Zirconia Ceramic beads

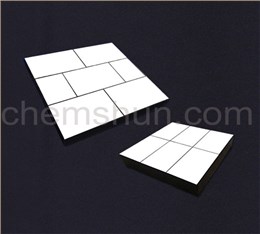

Zirconia Ceramic beads Rubber backed alumina ceramic tiles

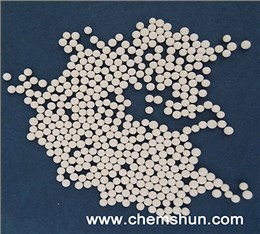

Rubber backed alumina ceramic tiles Zirconium Aluminium Silicate Beads

Zirconium Aluminium Silicate Beads Cement Mill Grinding Ball

Cement Mill Grinding Ball 95% Grinding Cylinder

95% Grinding Cylinder Ceramic Liner With Salient Point

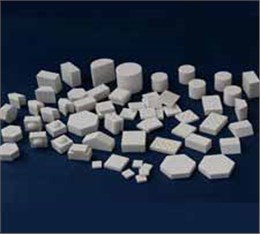

Ceramic Liner With Salient Point Hexagonal Alumina Tile

Hexagonal Alumina Tile Alumina Cylinder

Alumina Cylinder Ceramic Rubber Composite Liner

Ceramic Rubber Composite Liner Ceramic Epoxy Resin Glue

Ceramic Epoxy Resin Glue Wear Resistant Ceramic

Wear Resistant Ceramic Hex Rubber Ceramic Wear Plate

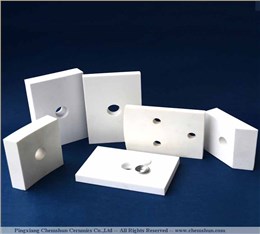

Hex Rubber Ceramic Wear Plate 95% Alumina Engineering Ceramics

95% Alumina Engineering Ceramics Alumina Ceramic Block

Alumina Ceramic Block Square Lagging Ceramics

Square Lagging Ceramics Curved Pipe Liner

Curved Pipe Liner Alumina Ceramics Lined Hopper

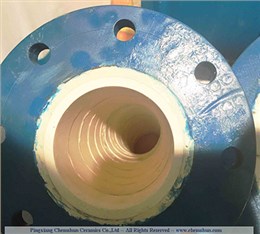

Alumina Ceramics Lined Hopper Ceramic Lined Pipe

Ceramic Lined Pipe Pulley Lagging Ceramics

Pulley Lagging Ceramics Technical Ceramics

Technical Ceramics Square Ceramic Rubber Component

Square Ceramic Rubber Component Weldable alumina tile

Weldable alumina tile Rubber Ceramic Wear Liner

Rubber Ceramic Wear Liner Ceramic Pipe Tile

Ceramic Pipe Tile 95%Al2O3 Ceramic Rubber Wear Liner With Bolt

95%Al2O3 Ceramic Rubber Wear Liner With Bolt Engineered Ceramic Lined Pipe

Engineered Ceramic Lined Pipe 92% Alumina Grinding Ball

92% Alumina Grinding Ball Ceramic Rubber Hose

Ceramic Rubber Hose Chemlok Glue For Vulcanization (252X)

Chemlok Glue For Vulcanization (252X) Dove-Tailor Ceramic Liner

Dove-Tailor Ceramic Liner Cyclone Pipe Liner

Cyclone Pipe Liner 90 degree pipe elbow

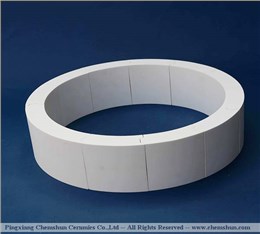

90 degree pipe elbow 92% Aluminium Oxide Pipe Ring

92% Aluminium Oxide Pipe Ring Ceramic Cone

Ceramic Cone Customized Technical Ceramics

Customized Technical Ceramics Alumina Tube

Alumina Tube Alumina Ceramics bricks

Alumina Ceramics bricks Abrasion Advanced Ceramics

Abrasion Advanced Ceramics Ceramic Cyclone Liner

Ceramic Cyclone Liner Cutting Ceramic Tile

Cutting Ceramic Tile Curved Pipe Liner

Curved Pipe Liner Ceramic Chute Liner

Ceramic Chute Liner Stock Bin

Stock Bin Coking Plant

Coking Plant Mill Bricks Liner

Mill Bricks Liner Ceramic Lining Glue 8280

Ceramic Lining Glue 8280