Upgrade your milling efficiency with ceramic grinding media balls

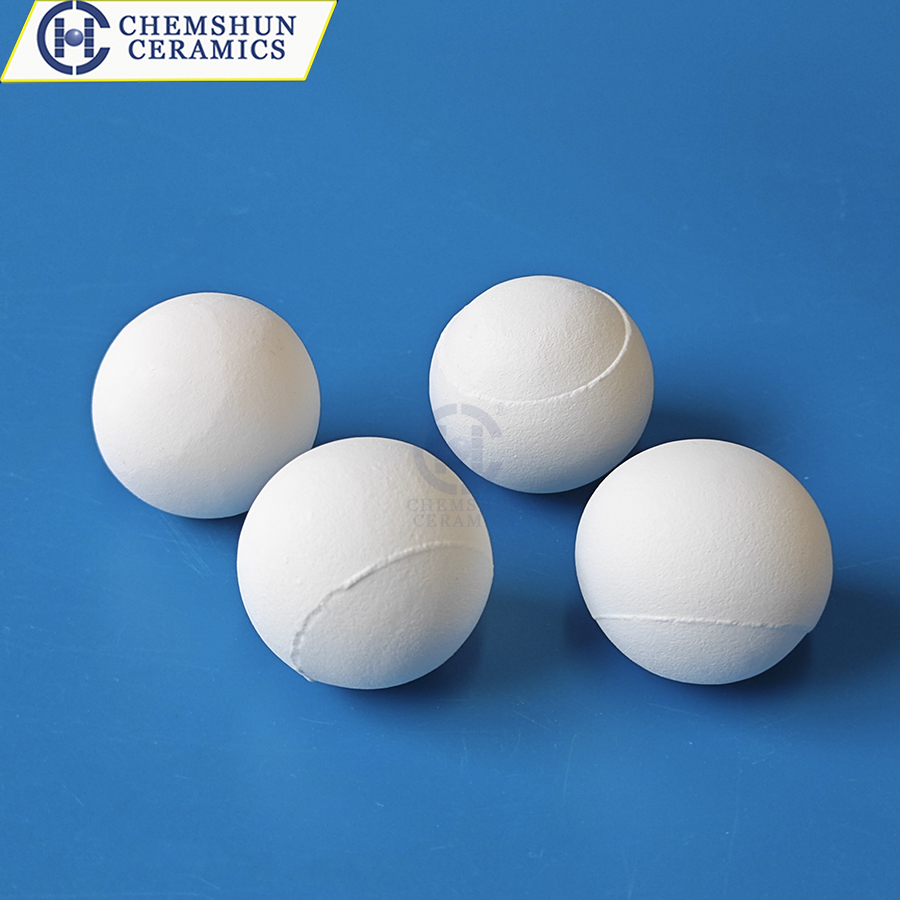

If you need media to crush materials in a ball mill, you want durable, dense, and impact-resistant ones. At the same time, they shouldn’t abrade your equipment from within during the cylinder rotation process. This is when you can’t go wrong with our ceramic grinding media balls.

Our products can make chrome steel and stainless steel beads a thing of the past as they offer advanced performance. These grinding media are same-sized and can be used to crush virtually any material in a ball mill without wreaking havoc on the latter. That is why they outperform their steel counterparts, finding a range of applications in dyestuff, pigment, cement, food processing, mining, and other industries.

As one of the major ceramic grinding media suppliers out there, Chemshun Ceramics can produce various types of milling options in different sizes. Some of our best-performing balls and beads include those made with:

· alumina

· zirconia

· ZTA

· yttria-stabilized zirconia

· ceria-stabilized zirconia

· silica

How to decide between alumina ceramic grinding media and other options?

Alumina milling balls are known for their excellent resistance to corrosion and wear and tear. They also greatly enhance the grinding performance of a mill. However, your choice of media composition should factor in the compatibility with the type of materials being ground as well as the ball mill lining to ensure the highest efficiency.

Apart from composition, you should take some other properties of ceramic grinding media balls into account. They include:

· Size. The rule of thumb is that your media are supposed to be larger than the materials being ground. In some cases, you can also mix different particle sizes in one operation cycle.

· Density. What makes us one of the best ceramic grinding media suppliers is that Chemshun Ceramics can produce beads and balls in many density options. Choose which one fits your materials.

· Hardness and contamination level. Alumina, zirconia, and other media differ in these features. Before deciding, consider the requirements of your particular grinding applications.

Whether you need alumina ceramic grinding media, ZTA beads, or other ones, we can help. Our products fit both vertical and horizontal ball mills and can be used for a plethora of materials in wet and dry applications.

If you still have a hard time choosing, contact us so that we can give you a few pointers to meet your grinding needs. Or let’s discuss your OEM or ODM project.

Ceramic Gringing Media

Ceramic grinding media is wide application in ball mill of cement, ceramic, mining, pigment, dye, ink, paint industry for improve the grinding efficiency and improve the performance of product.

Chemshun ceramic grinding media include ceramic grinding balls and grinding cylinders. Our milling balls/ cylinders have characters of high hardness, superior resistance of impact and wear, and uniform size and good roundness.

Chemshun produce ceramic grinding ball media with different diameter ranger, density and composition to meet different customer needs and kinds of ball mills. We accep OEM and ODM of ceramic grinding media.

| Item | Main Composition | Diameter | Density | Application Industry |

| CS-26 | Al2O3, SiO2 | 0.5~20 | 2.6~2.8 | Mineral |

| CS-32 | Al2O3, SiO2,ZrO2 | 0.5~20 | 3.2~3.3 | Ceramic, Mining, Mineral |

| CS-36 | Al2O3 | 0.4~25 | 3.5~3.75 | Ceramic, Mining, Mineral, Cement, Pigment |

| CS-40 | ZrO2, SiO2 | 0.4~5.0 | 4.0~4.2 | Mining, Mineral, Paint, Pigment, Dyestuffs |

| CS-52 | ZrO2, Al2O3 | 0.4~5.0 | 5.1-5.3 | Mining, Mineral, Paint, Pigment, Dyestuffs |

| CS-60 | ZrO2, Y2O3 | 0.2~40 | 5.95~6.05 | 1. Chemical materials, paint, printing, ink, pigment. 2. Advanced ceramics pastes or powder. 3. Electronic pastes: gold platinum, silver, cuprum, nickel. 4. Food stuff, pharmaceuticals, cosmetics. |

| CS-62 | ZrO2, CeO2 | 0.6~4.0 | 6.1~6.2 |

-

92% Dry Grinding Media Balls

92% Dry Grinding Media Balls -

92% High Alumina Grinding Ball

92% High Alumina Grinding Ball -

75% Alumina Ceramic Bead

75% Alumina Ceramic Bead -

Zirconia Ceramic Beads

Zirconia Ceramic Beads -

Zirconia Silica Beads Balls

Zirconia Silica Beads Balls -

92% Al2O3 Dry Grinding Ball

92% Al2O3 Dry Grinding Ball -

Ceramic Grinding Media

Ceramic Grinding Media -

ZTA320 ZTA380 ZTA450 Ceramic Beads

ZTA320 ZTA380 ZTA450 Ceramic Beads -

Alumina Ceramic Grinding Balls (Al2O3 68% 75% 92% 95%)

Alumina Ceramic Grinding Balls (Al2O3 68% 75% 92% 95%) -

Yttria-stabilized zirconia grinding beads

Yttria-stabilized zirconia grinding beads -

Ceria-stabilized Zirconia Beads

Ceria-stabilized Zirconia Beads -

Zirconia Toughened Alumina Beads

Zirconia Toughened Alumina Beads

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

Factory 1 Address: Jilin East Road, Anyuan Industrial Area, Anyuan District, Pingxiang City, Jiangxi Province, P.R.China.

Factory 2 & Office Address: No.16, Jinguang Avenue, Anyuan Industrial Area, Anyuan district, Pingxiang City, Jiangxi Province. P.R.China.