Product Name:92% Dry Grinding Media Balls

- Product Category:

- Product Details:

- E-Mail:

Product Description :

Alumina grinding balls dry grinding are made of imported low-sodium microcrystalline alumina powder. With high density, high hardness, high wear-resistance, good shock resistance, good corrosion resistance, no pollution to grinded the material, alumina dry grinding balls are the most ideal ball mill grinding media for grinding Powder, resin, ceramics, mining such as quartz sand, aluminum oxide powder, corundum, lithium feldspar etc. It can keep the purity and improve the stability of the grinded materials.

Chemshun Dry Grinding Ball Advantage :

-- Advantage of Raw Material :

Imported low-sodium microcrystalline alumina powder.

--- Advantage of Press Process :

① Using a 2000tons dry bag isostatic press, the molding pressure is transmitted and distributed more evenly;

② 80-100MPa high-pressure pressing has strong pressure penetration and high green density consistency, which solves the problem of large internal wear caused by low pressure and low internal density of the ball in traditional pressing methods;

③ The spherical roundness is high (<2mm) and the protrusion is small, which solves the problem of the ball is not resistant to impact due to the over-sized spherical protrusion of the traditional pressing method.

--- Advantage of Sintering Process

① Intelligent temperature-controlled shuttle kiln has a high degree of automation, the firing temperature rise rate can be adjusted according to product quality requirements, and it is highly flexible;

② The firing time is long, and the unique firing process achieves a small temperature difference (±5°C), more uniform heating, more transparent sintering, and good porcelain consistency.

Technical Data :

Item | Properties | Unit | Chemshun Value |

1 | Al2O3 | % | 92-93.5 |

2 | Density | g/cc | 3.65±0.05 |

3 | Moh’s hardness | Scale | 9 |

4 | Rockwell hardness | HRA | 87 |

5 | Water Absorption | % | ≤0.01 |

6 | Self abrasion(24h) | % | ≤0.1‰ |

7 | Color | white | |

8 | Dimension | mm | 30,40,50,60,70 |

CHEMSHUN Impact and Abrasion Test Methods

-- Impact Resistance drop test

Fully-automatic impact resistance testing equipment:

① Impact resistance test under simulated working conditions: a free fall height of 3.5 meters, and the balls impact each other solidly;

② Method: 10 balls in a group, dropped cyclically, 10 times in one cycle, 60 cycles of impact, and calculated breakage rate of balls;

③ Standard: Only small pieces of ball surface are allowed to fall off .

The number of damaged items after 60 cycles is ≤2 ( as an internal testing standard ).

--- Wear loss test

Take 4kg dry grinding ball and weigh the net weight, pour it into the test grinding jar, pre-grind for half an hour to remove surface impurities, clean and dry, weigh M1,

Pour it into the test grinding jar, add grinding sand (corundum sand), and dry grind together After 24 hours, wash and dry, and weigh M2.

W(wear loss)=1000*(M1-M2)/(M1*24)

Chemshun Dry Grinding Balls Features :

1) High abrasion resistance

2) High fracture toughness

3) High corrosion resistance

4) High hardness

5) High grinding efficiency

6) Low wear loss

7) Smooth surface

8) No pollution to grinded the material

9) Special process production for dry mill environment

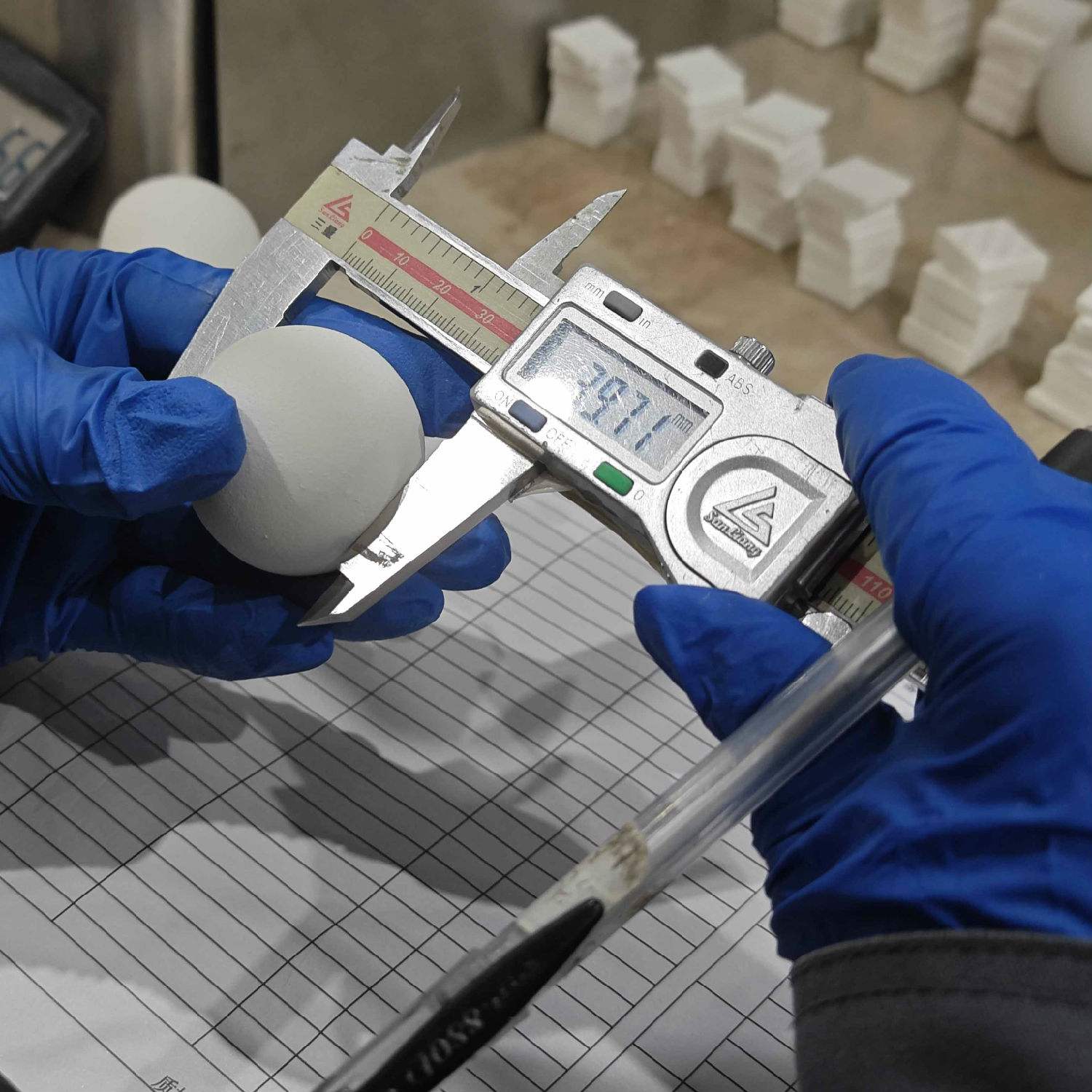

Chemshun Balls Inspection :

1) Grinding balls Size Inpection 2) Balls Surface Inspection

Package :

| Company name: | Please fill in your company name |

| * E-mail: | |

| Source: |

|

| * Inquire intention description: | |

| Please fill in the quantity and description of Inquire products for uniform stocking. | |

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

ADD:Non-metal area of shangliuyuan, Economic development zone, pingxiang city, Jiangxi province, P.R.China

- comments in total【Write a Review】Customer Reviews