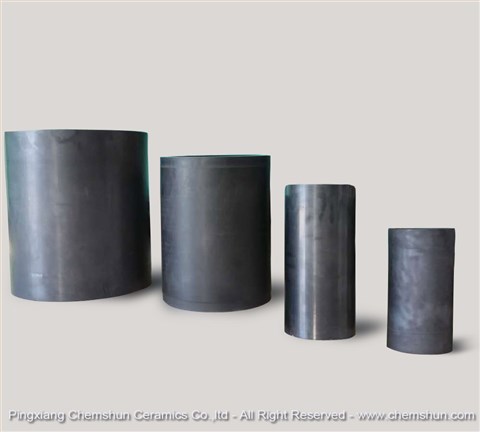

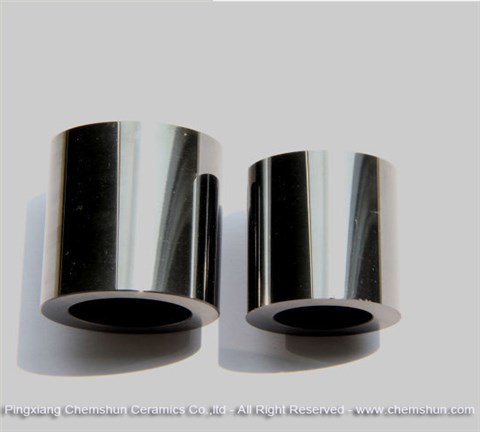

SSiC Silicon Carbide Grinding Barrel Grinding Cylinder

Description :

Silicon Carbide was originally produced by a high temperature electro-chemical reaction of sand and carbon. Silicon carbide is an excellent abrasive and made into grinding wheels and other abrasive products. Today the material has been developed into a high quality technical grade ceramic with very good mechanical properties. It is used in abrasives, refractories, ceramics, and a large number of high-performance applications. Silicon Carbide can also be made an electrical conductor and has applications in resistance heating, flame igniteand electronic components.

Chemshun high hardness Silicon carbide, firing as pressureless sintered way, as SSiC ceramic grinding barrel / bushing liner / lining tube with high strength,high wear resistantce are widely used in papermaking, chemical, electronics, pharmaceutical and other ink jet, lithium battery materials, electronic pulp nano-ceramic sanding machines.

Characteristic

1. High Hardness, Out Standing Wear Resistance

2. High Strength Over A Wide Temperature Range

3. Excellent Thermal Shock Resistance

4. Excellent Oxidation Resistance

5. Very Low Friction Coefficient

6. Low Thermal Expansion and High Thermal Conductivity

Application:papermaking, chemical, electronics, pharmaceutical and other ink jet, lithium battery materials, electronic pulp nano-ceramic sanding machines.

Package :Export Carton, Wooden Box

Delivery:Usually 21-30days for 20 ton.

Technical Data :

Properties | SSiC |

Bulk denstity SiC (Vo1%) | ≥99 |

Bulk density (g/cm3) | 3.10-3.15 |

Apparent porosity (%) | <0.2 |

Modulus of rupture at 20℃ (Mpa) | 400 |

Modulus of rupture at 1200℃ (Mpa) | 650 |

Modulus of elasticity at 20℃ (Gpa) | 410 |

Thermal Conductivity at 1200℃ (w.m-1.k-1) | 55 |

Thermal expansion at 1200℃ (a×10-6/℃) | 4.0 |

Thermal shock resistance at 1200℃ | Very good |

Max.working temperature (℃) | 1600 |

Ceramic Tile Liner

Ceramic Tile Liner Weldable alumina tile

Weldable alumina tile Curved Pipe Tile Liner

Curved Pipe Tile Liner Alumina Ceramic Pipe Liner

Alumina Ceramic Pipe Liner AL92 Ceramic Rubber Chute Liner

AL92 Ceramic Rubber Chute Liner Trapezoidal Pipe Tile

Trapezoidal Pipe Tile 90 degree pipe elbow

90 degree pipe elbow Wear Resistant Ceramic Liner

Wear Resistant Ceramic Liner (SISIC) Silicon Carbide Ceramic Plate

(SISIC) Silicon Carbide Ceramic Plate Cyclone Pipe Liner

Cyclone Pipe Liner 92% Aluminium Oxide Pipe Ring

92% Aluminium Oxide Pipe Ring 92% High Alumina Grinding Ball

92% High Alumina Grinding Ball Ceramic Liner With Salient Point

Ceramic Liner With Salient Point Alumina Cylinder

Alumina Cylinder Ceramic Rubber Composite Liner

Ceramic Rubber Composite Liner Ceramic Epoxy Resin Glue

Ceramic Epoxy Resin Glue Zirconia Ceramic Beads

Zirconia Ceramic Beads Hex Rubber Ceramic Wear Plate

Hex Rubber Ceramic Wear Plate 95% Alumina Engineering Ceramics

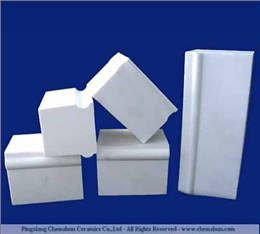

95% Alumina Engineering Ceramics Alumina Ceramic Block

Alumina Ceramic Block Square Ceramic Tile

Square Ceramic Tile Alumina Ceramics Lined Hopper

Alumina Ceramics Lined Hopper Ceramic Lined Pipe

Ceramic Lined Pipe Pulley Lagging Ceramics

Pulley Lagging Ceramics Technical Ceramics

Technical Ceramics Square Ceramic Rubber Component

Square Ceramic Rubber Component Rubber Ceramic Wear Liner

Rubber Ceramic Wear Liner Rubber backed alumina ceramic tiles

Rubber backed alumina ceramic tiles Engineered Ceramic Lined Pipe

Engineered Ceramic Lined Pipe SSIC Ceramic Seal Ring

SSIC Ceramic Seal Ring Yttria-stabilized zirconia grinding beads

Yttria-stabilized zirconia grinding beads Mining Ceramic Grinding Balls

Mining Ceramic Grinding Balls Cement Mill Grinding Ball

Cement Mill Grinding Ball Ceramic Rubber Hose

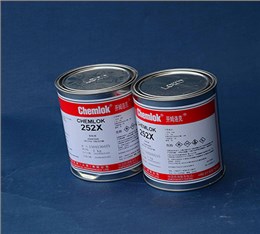

Ceramic Rubber Hose Chemlok Glue For Vulcanization (252X)

Chemlok Glue For Vulcanization (252X) Dove-Tailor Ceramic Liner

Dove-Tailor Ceramic Liner 95% Grinding Cylinder

95% Grinding Cylinder Ceramic Cone

Ceramic Cone Customized Technical Ceramics

Customized Technical Ceramics Alumina Tube

Alumina Tube Alumina Ceramics bricks

Alumina Ceramics bricks Abrasion Advanced Ceramics

Abrasion Advanced Ceramics Hexagonal Alumina Tile

Hexagonal Alumina Tile Ceramic Cyclone Liner

Ceramic Cyclone Liner Cutting Ceramic Tile

Cutting Ceramic Tile Curved Pipe Liner

Curved Pipe Liner Ceramic Chute Liner

Ceramic Chute Liner Stock Bin

Stock Bin Coking Plant

Coking Plant Mill Bricks Liner

Mill Bricks Liner SIC Cyclone

SIC Cyclone Silicon Carbide Bulletproof Tiles

Silicon Carbide Bulletproof Tiles Ceramic Lining Glue 8280

Ceramic Lining Glue 8280