Top articles

- Application of wear-resistant ceramic pipes

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Latest articles

- Application of wear-resistant ceramic pipes

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

Your browsing history

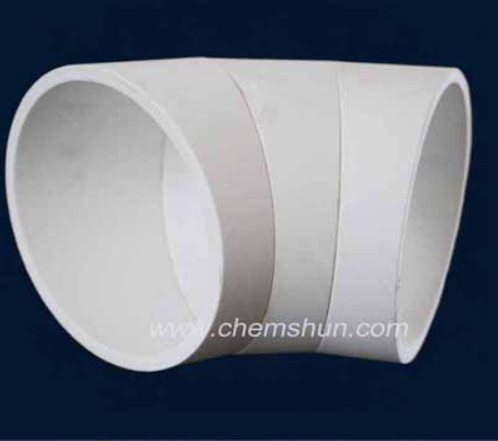

Application of wear-resistant ceramic pipes

As a high-performance industrial pipeline material, wear-resistant ceramic pipes have shown extensive application potential in many industrial fields due to their excellent wear resistance, corrosion resistance, high strength and long life. The following is a professional explanation of the main fields where wear-resistant ceramic pipes can be applied:

1. Mining and mineral processing industry: During ore mining, transportation and processing, wear-resistant ceramic pipes can effectively resist the erosion and wear of hard materials such as ores and rocks, significantly improve the service life of the pipeline and reduce maintenance costs. It is especially suitable for harsh environments such as ore slurry and tailings transportation systems.

2. Power and energy industry: In coal-fired power plants, biomass power plants and other places, wear-resistant ceramic pipes are often used to transport highly abrasive media such as coal powder and ash, effectively preventing pipelines from leaking due to long-term wear, ensuring stable operation of the system and reducing downtime maintenance time.

3. Steel and metallurgical industry: In the smelting, rolling, coking and other processes of steel mills, wear-resistant ceramic pipes perform well in transporting high-temperature molten metals, slag and corrosive media, and can withstand extreme temperature and pressure conditions to ensure the continuity and safety of the production process.

4. Cement and building materials industry: In the process of conveying cement clinker, raw material, gypsum powder and other powder materials, wear-resistant ceramic pipes can effectively resist the high-speed erosion and wear of materials, reduce energy consumption, improve conveying efficiency, and resist the erosion of corrosive media such as cement slurry.

‘5. Chemical industry: For the conveying of corrosive media such as strong acids and strong alkalis, the inner lining of wear-resistant ceramic pipes provides excellent chemical stability, effectively preventing the corrosion of the pipeline by the medium, ensuring production safety, and is suitable for chemical reactor outlets, acid and alkali liquid conveying pipelines, etc.

In summary, wear-resistant ceramic pipes have shown irreplaceable application value in multiple industrial fields with their unique performance advantages. They are one of the important materials for improving production efficiency, reducing maintenance costs, and ensuring safe production.