As a kind of high performance material, wear-resistant ceramics are widely used in grinding machines because of their excellent wear resistance, high hardness and corrosion resistance.

Wear-resistant ceramics are made of alumina as the main raw material and rare metal oxides as the flux, which are roasted at 1700 degrees. This special corundum ceramics has a very high hardness, its Rockwell hardness can reach HRA80-90, second only to diamond, wear resistance is far more than wear-resistant steel and stainless steel. The wear resistance is 266 times that of manganese steel and 171.5 times that of high chromium cast iron. In addition, the density of wear-resistant ceramics is only 3.6-3.9g/cm3, about half that of steel, which greatly reduces the load of the equipment.

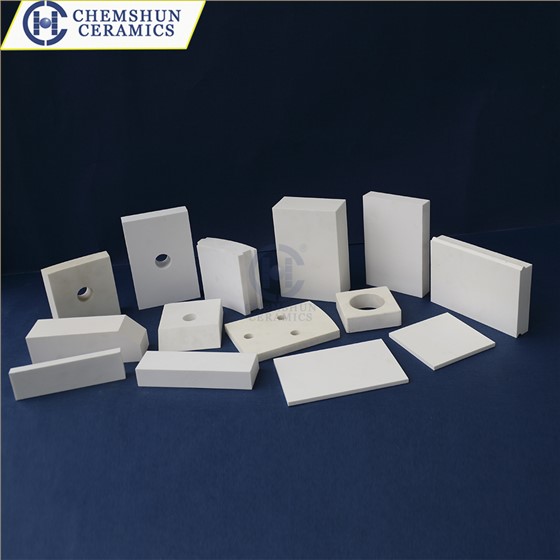

In the ball mill, wear-resistant ceramic lining brick is an indispensable and important part. This lining brick is usually installed inside the cylinder of the ball mill and is closely fitted with the cylinder to effectively protect the cylinder from wear. The use of ceramic lining bricks with ceramic balls can significantly improve the fineness of grinding, reduce metal impurities, and thus improve the purity of the material. This design not only extends the service life of the ball mill, but also expands its application range, making it suitable for grinding a variety of materials from high-purity silicon dioxide to alumina, zirconia special ceramics, from medicine to glazes.

Advantages of wear-resistant ceramics used in ball mills:

can improve the service life of the mill equipment. Under the same working conditions, the use of wear-resistant ceramics mill can extend the service life of the equipment more than ten times.

wear-resistant ceramic lining brick and ceramic ball used together, can reduce metal impurities, improve the purity of the material, especially suitable for high quality material grinding process.

the application of wear-resistant ceramics reduces the wear of the equipment, reduces the frequency of maintenance and replacement, thus reducing the production cost.

Ceramic Tile Liner

Ceramic Tile Liner Alumina Ceramic Pipe Liner

Alumina Ceramic Pipe Liner AL92 Ceramic Rubber Chute Liner

AL92 Ceramic Rubber Chute Liner Wear Resistant Ceramic Liner

Wear Resistant Ceramic Liner